There can be many reasons for the breakdown of a washing machine. The most common of them are: consumer mistakes made during operation, incorrect loading of laundry, low-quality detergents for washing, factory defects during production, too hard tap water, etc.

Any element of a household appliance can fail. Depending on the severity of the problem, downtime may be required. washing machine repair, which is made at home independently. In more serious cases, you will have to seek help from a professional technician who can determine the cause and make complex repairs.

The most important part of a washing machine is the engine. Its main task is to rotate the drum. Its breakdown can lead to a serious problem, up to the failure of the entire washing machine.

![]() See also - The washing machine is electrified - what to do?

See also - The washing machine is electrified - what to do?

Types of washing machine motors

Automatic washing machines that are currently in consumer homes can have one of three types of electric motors:

- Asynchronous, used in older models. The simple structure, consisting of a starter and a rotor, has a low cost and operates quietly. But due to its large dimensions and low efficiency in modern machines, this motor is not used;

- Collector, it is this type that is used in most modern models of machines. Belt transmission of rotation from the engine to the drum. Compared to the previous type, it has a smaller size, high operating speed and is independent of the frequency of the electrical network. Basic structural elements: starter, rotor, tachogenerator, electric brushes. Very often, you can repair such an engine yourself;

- Brushless or direct drive motor. A striking example of modern washing machines with this type of engine is the LG range. Directly connected to the drum, without a belt. Such a motor is three-phase, the collector is multi-pole, and the rotor is permanent magnet. It has a similar structure to asynchronous, but smaller in size, with high efficiency, hence the expensive cost of such devices.

How to diagnose an electric motor at home?

It is easiest to check the commutator motor for proper operation. It is easier to remove at home and can be checked without the use of expensive professional equipment.

As for electric motors with direct drive, a control system is needed for their diagnosis, and it will have to be removed along with the tank, since it is an integral part of it. The stator is bolted to the frame of the washing machine itself, the rotor also has a rigid mount, which in most cases is not collapsible. Repair of such washing machines is most often carried out only in service centers.

How to check a direct drive motor?

Most often, such a motor can be checked only by analyzing the errors generated on the display or the service menu of the washing machine.By the error code that appears on the display, it is possible to detect a turn circuit, diagnose a power outage, failure of brushes.

A more complex and professional check and repair is carried out by qualified craftsmen using special laboratory and bench equipment.

How to check a brushed motor?

The most common engine used in modern models of washing machines. You can check the collector motor of the washing machine yourself at home. First, the electric motor must be removed from the machine body. First, unscrew the back or front wall of the case (depending on the model of the washing machine). The motor itself is located under the tank at the back and is attached to the metal frame with studs or bolts. The electrical connection is equipped via terminals that are easily disconnected.

After the motor is removed, it is necessary to make a series connection of the stator and the rotor, and apply a 220 W mains voltage to the ends. It is best if it will be supplied through additional ballast. You can use a heating element as it, the main thing is that the power of equipment with active resistance is at least 500W. If, after connecting to the mains, the motor rotates, and the autotransformer does not heat up much, at this stage it is possible to diagnose the normal operation of the motor.

The most common causes of engine breakdown

- Failed electric brushes;

- Breakage of the winding in the rotor and stator;

- Collector lamellas.

Replacing the electric brushes

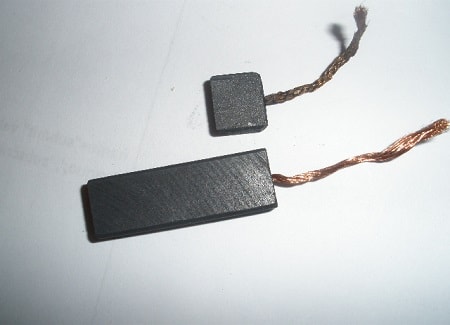

These are conductive graphite cubes with wires that rub against the collector.

The reason for replacing the motor brushes may be:

- loss of rotational force of the drum or complete stop;

- unusual noise during operation of the washing machine.

The most common cause of failure is overloading the tank. Also, the electric brushes quickly wear out when using the spin at maximum speed or due to a short circuit in the turns of the electric motor winding, problems with the belt that connects the motor to the drum, it can jump off the pulley or break.

A visual inspection of the brushes will also help to understand about the need for replacement. If during operation they spark or there is a black coating on the surface, the parts need to be changed.

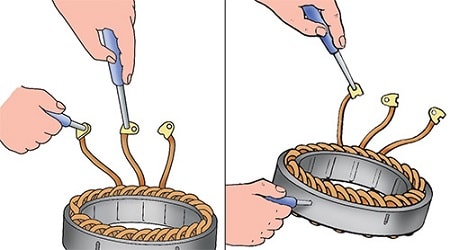

Of course, this is an inexpensive engine element, and repairs can be done at home. It is enough to buy a suitable model of brushes in a specialized store or service center. The main thing is to choose and replace the brushes on the washing machine, they must fully correspond to the type of motor and it is better if it is an original set from the manufacturer of the washing machine itself.

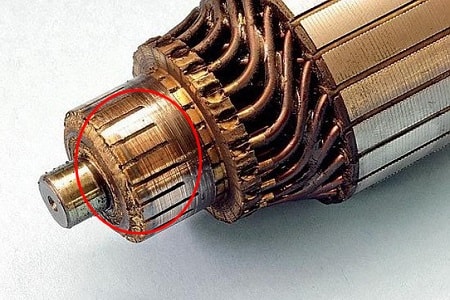

Replacement of lamellas required

This is exactly the part of the collector on which the electric brushes slide. Through them, the current is transmitted through the rotor winding to the motor. The plates themselves are rarely subject to wear, the breakage of the cord in the winding in the places where the lamellas are attached or their separation can become the cause of breakage.

This happens, most often, also due to improper operation of the device, for example, in a top-loading machine, the washing process was started with the drum flaps open or bearing failure.

If the delamination is small, the repair is carried out on a special machine, by grooving the collector. At home, you can get by with a simple fine sandpaper. The principle is the same - the lamellas are sharpened, then the space between them is carefully cleaned of dust and trapped chips.

You can check the electric motor for this malfunction by slowly scrolling the rotor, if a characteristic sound appears, then, most likely, the reason is in the lamellas.

Open or short circuit in the rotor or stator winding

These are the most common reasons for the loss of engine power or complete cessation of its operation, which can be the result of:

- overheating of the motor housing caused by short circuits in the winding.The normal temperature should not be higher than 80 degrees, if it rises to 90 degrees, the thermostat is triggered to stop the motor;

- violation of the insulation of the winding. In this case, repairs at the service center are inevitable. Most often, you have to change the entire engine. It is not recommended to do the winding again at home.

A break in the winding can be detected with a multimeter in the mode of measuring the resistance between lamellas. Norm 0.1-0.4 Ohm.

A breakdown or short circuit in the electric motor of the washing machine can cause malfunction and failure of other parts of the device, for example, the command apparatus (another expensive part of the machine), power triac, reverse relay. As you can see, the most common causes of breakdowns are non-compliance with the operation or instability of the electrical network. To increase the service life, it is recommended to use the device according to the instructions, and to protect against power surges, install a difavtomat and connect the washing machine only through this protective device.

See also:

- 10 best ATLANT washing machines according to customer reviews

- 10 best built-in washing machines

- 10 best washing machines under 15,000 rubles according to customer reviews

- 10 best washing machines under 25,000 rubles according to customer reviews

- 13 best washing machines from 40,000 to 50,000 rubles according to customer reviews

Not a comment but a question.

The machine drained the water and the spin did not start. There was no smell of burning, no noise, nothing - it just didn't turn on and the F-21 malfunctioned - the engine was faulty. If I did not start spinning (high speed), then the end of the brushes. He took off the engine - yes, the brushes are in the trash. replaced, but the display still shows the F-21 check and the machine does not start. How do I remove the lock?

There is information on the Internet how to remove this error. We do not have this article yet. We know for sure that she is cleaning