In this article we will tell you how to check the refrigerator compressor for performance, describe its design and the device of this element. The compressor is one of the main components of the refrigerator, so to speak, the "heart". If it does not start, refuses to work, then the unit itself will cease to function. Is it possible to personally repair this part of the refrigerator if there is a suspicion of its malfunction? It is possible, however, this requires certain knowledge and skills.

How does a refrigerator compressor work

In the back of the refrigerator, from below, we usually see the compressor housing, it is usually painted black, inside which it is hermetically sealed. He is in a state of weightlessness, in an oil bath. Compressors for most models of household refrigerators do not differ in design. Usually their design is presented in the form of a reciprocating electric motor with a starting winding powered by an alternating current. Principle of operation: the compressor constantly creates pressure, under the action of which the vapors of the refrigerant (freon) enter the condenser, where they are cooled and go further in the form of a liquid through copper pipes, cooling the inside of the refrigerator and taking heat, after which it enters the evaporator, and from it back into the compressor. The process is cyclical. Naturally, if the engine does not turn on, then the system will not function.

There are three terminals on the compressor housing. They are made in the form of pins and are located at the bottom of the compressor, forming a triangle. One of the contacts comes from the starting winding, the other from the working winding, and the third has one common terminal. Also, any compressor includes a relay - a device that starts the engine. It connects to three pins and usually looks like a small box. In more modern refrigerators, in which the activation speed is regulated, the compressor is connected to another box, made using more complex electrical circuits.

Causes of a malfunction of an electrical device:

- burnt out compressor;

- damaged start relay;

- the cable to which the appliance is connected is faulty or damaged.

It will be logical to first check the cable itself, and then proceed to inspect the possible malfunction of the remaining parts of the device, if the cable is working properly.

Also, sometimes there are cases when the compressor turns on, buzzes, the light is on, but it does not cool or cool, but very weakly. In this case, you need to pump refrigerant into the compressor, in our case it is freon, because it most likely follows. In this case, it is necessary to call a foreman who will find the leak and pump gas.

See also:

- 7 best Bosch refrigerators according to customer reviews

- 8 Best Samsung Refrigerators According to Buyers

- 9 Best Inexpensive Refrigerators According to Buyers

- 10 best LG refrigerators according to customer reviews

Dismantling the compressor

In order to dismantle the compressor you will need the following tools:

- multimeter;

- nippers (pliers);

- blowtorch.

First you need to bite into the copper pipes connecting the compressor to other elements. Gas (freon) will begin to come out of them. It is explosive, so it is necessary to dismantle it away from sources of fire, and it is also recommended to do it in a well-ventilated area. After all the gas is gone, you can continue to work. It is required to separate the remaining pipes with a burner and disconnect the compressor from the base, while unscrewing the bolts. Next, open the starting relay with a screwdriver.

![]() See also - How to rebalance the refrigerator door yourself?

See also - How to rebalance the refrigerator door yourself?

Resistance test

The next step that must be taken if the compressor is not working properly is to check the resistance, because if damaged, it may give an electric shock. This is due to the fact that the winding has been damaged, and the voltage from it jumps to the case. This happens most often with old units. This is checked by measuring the resistance of each of the three contacts together with the refrigerator body, while it is necessary that there is no paint in the place that is ringing. The multimeter should show “infinity” on the display, i.e. do not show anything, otherwise your compressor is unusable.

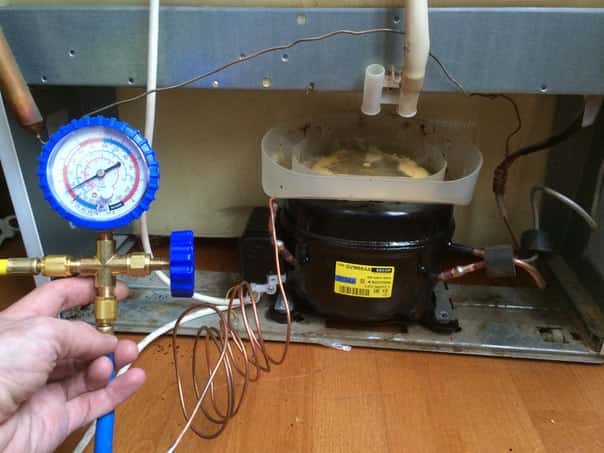

Pressure test

If the resistance test does not give results, but the refrigerator is still not working, you should check it with a pressure gauge, i.e. check the pressure inside the case. It is necessary to connect the simulator to the discharge connection and take the readings with the compressor on. If the pressure gauge shows a pressure of 6 atmospheres, and this figure is rasterized, in this case the refrigerator is working properly. If lower, then you will need to replace the compressor housing.

Checking the current

Another of the most important steps is to check the relay, or whether the current reaches the electric motor. It is advisable to take a working relay that has been checked and tested. It is advised to use a multimeter with a clamp.

After connecting the working relay to the compressor, you must turn it on and connect a multimeter. This must be done by clamping one of the wires with pliers. Depending on the engine power, the tester readings will also change. With a motor power of 140 W, the display should be 1.3 A. A with a power indicator of 120 W from 1.1 to 1.2 A. In these cases, the relay is fixed. in most cases it fails, then it is worth checking it.

See also:

- 10 best Atlant refrigerators according to owner reviews

- 10 best refrigerators from 30,000 to 40,000 rubles according to buyers

- 11 best BEKO refrigerators according to customers' opinion

- 15 best Liebherr refrigerators according to customer reviews